With great pleasure, we will explore the intriguing topic related to cummins isl 8.9 map sensor. Let’s weave interesting information and offer fresh perspectives to the readers.

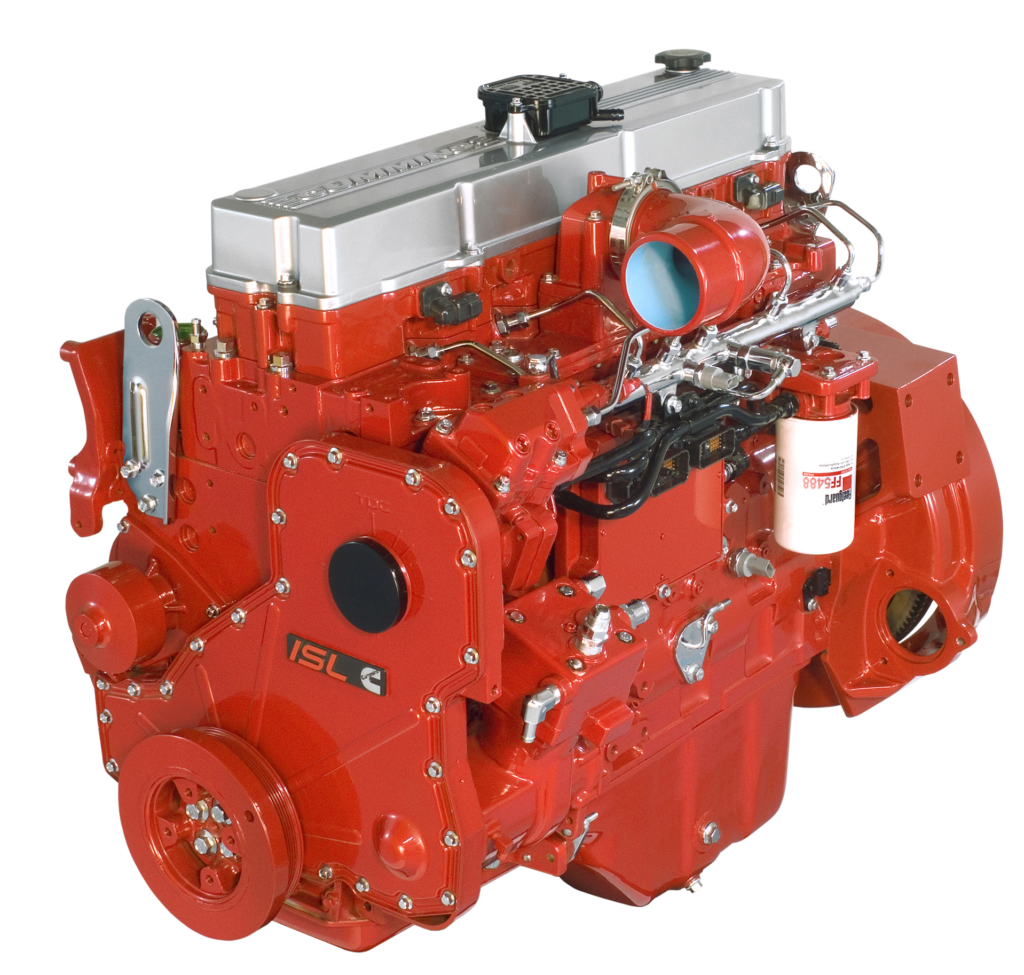

The Cummins ISL 8.9 engine, a powerhouse in the trucking and heavy-duty equipment industries, relies on a sophisticated network of sensors to ensure optimal performance. Among these, the Manifold Absolute Pressure (MAP) sensor plays a crucial role in regulating engine operation and maximizing fuel efficiency. This article delves into the workings of the MAP sensor, its significance in the ISL 8.9 engine, common issues, and troubleshooting strategies.

The MAP sensor, a critical element in the engine’s Electronic Control Module (ECM), measures the absolute pressure within the intake manifold. This pressure, directly related to the density of air entering the cylinders, provides the ECM with essential data for calculating the ideal fuel-to-air ratio. By accurately sensing manifold pressure, the MAP sensor allows the ECM to:

The MAP sensor, typically a piezoresistive or capacitive device, converts pressure variations into an electrical signal. This signal, interpreted by the ECM, provides a real-time snapshot of the pressure within the intake manifold.

The Cummins ISL 8.9, a powerful and reliable engine, relies heavily on the MAP sensor for optimal performance. Its significance can be summarized as follows:

While the MAP sensor is generally robust, it can be susceptible to certain issues, leading to engine performance problems. Some common issues include:

A: The MAP sensor does not have a specific replacement interval. However, it’s recommended to replace it if it fails or exhibits signs of malfunction.

A: It is not recommended to clean a MAP sensor as it can damage the sensitive internal components.

A: Replacing the MAP sensor is generally a straightforward procedure, but it’s essential to consult the service manual for your specific engine model.

The MAP sensor, a critical component in the Cummins ISL 8.9 engine, plays a vital role in regulating engine operation and maximizing fuel efficiency. By accurately sensing manifold pressure, the sensor allows the ECM to optimize fuel injection, adjust timing, monitor boost pressure, and detect vacuum leaks. Understanding the workings and importance of the MAP sensor, along with troubleshooting strategies and maintenance tips, can help ensure the smooth and efficient operation of the ISL 8.9 engine, contributing to optimal performance, fuel economy, and reduced emissions.

Thus, we hope this article has provided valuable insights into cummins isl 8.9 map sensor. We hope you find this article informative and beneficial. See you in our next article!

Navigating the City of Angels: Google Maps and the Bangkok Experience Related Articles: Navigating the City of Angels: Google Maps…

The Crucial Role of the Manifold Absolute Pressure (MAP) Sensor in Modern Automobiles Related Articles: The Crucial Role of the…

Mapping the Inferno: Understanding California’s Wildfire Crisis Through Spatial Analysis Related Articles: Mapping the Inferno: Understanding California’s Wildfire Crisis Through…

Your email address will not be published.